Krishna Rastogi

Optimization and design of 5 liter bioreactor for the production of Biodiesel

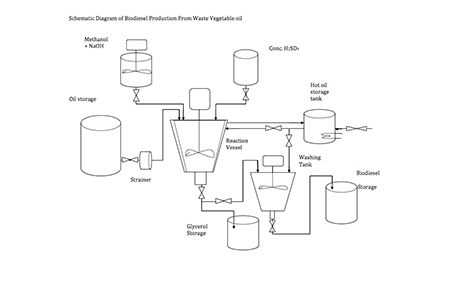

The process condition were optimized for the production of biodiesel from different sources like waste vegetable oil, pork rind(skin),chicken skin in lab scale. The efficiency of the biodiesel obtained was approx. 97%.The process was scaled up to 5 liter (manual mode).Later on this was scaled up to 25 liter. The 25 liter bioreactor is on installation stage (automated mode).

● Optimization of parameters in the process of production of biodiesel to get the maximum yield of Glycerol.

● To carry out Glycerol purification and achieve a High purity product with minimal color.

● To study the effects varying the concentration of acid, type of polar solvent along with amount of Activated Charcoal used for Adsorption on the purity of Glycerol.

● Analysis of purity of glycerol by performing Assay Test.